- Use:

-

Textile Finishing Machinery

- Type:

-

PU roller

- Warranty:

-

3 months

- Condition:

-

New

- Applicable Industries:

-

Machinery Repair Shops, Retail, Other, textile spare parts

- Weight (KG):

-

1

- Video outgoing-inspection:

-

Not Available

- Machinery Test Report:

-

Not Available

- Marketing Type:

-

Ordinary Product

- Place of Origin:

-

Jiangsu, China

- Brand Name:

-

topt

- Material:

-

metal

- Package:

-

Single Piece Package

- Quality:

-

Guaranteed

- item name:

-

Chenillle

- Machine Type:

-

PU roller

- Shiping:

-

by courier /air / sea

- Payment Term:

-

T/T, Paypal, Western Union

- Delivery time:

-

3-5 Working Days

- HS CODE:

-

8448399000

- After Warranty Service:

-

Video technical support

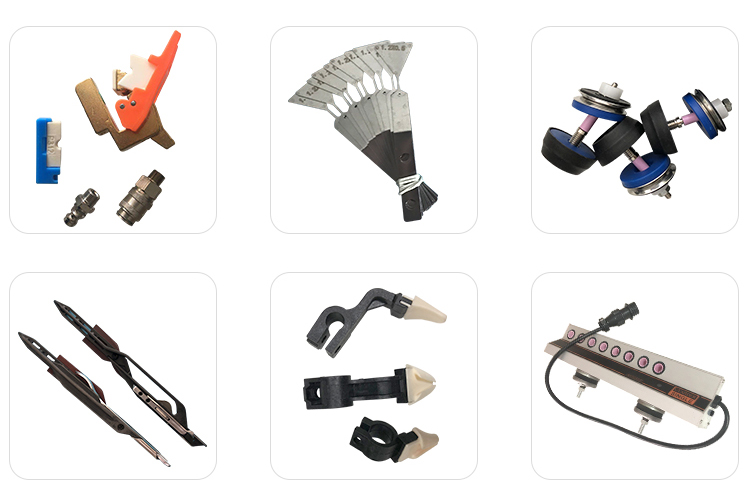

Chenille machine introduce:

Chenille spinning machine, also known as chenille machine, is a new spinning equipment for producing and processing chenille yarn. The domestic model of the machine is redesigned and manufactured after transplantation on the basis of digesting and absorbing the prototype of foreign exhibitors. Its products are called chenille yarn or spiral thread and broken thread. It is a new variety of fancy thread. It is also called chenille because it looks like a rope. The utility model uses two strand wires as the core wire, and the short pile yarn cut by the blade is clamped between the two core wires through twisting. Chenille thread is widely used in many fields, such as home textile decorative fabrics, machine knitted clothing, automobile decoration products, antique fabrics and so on. In recent years, it has become a new bright spot in the field of new textile product development and a new growth point of enterprise economic benefits.

Operation methods and precautions

Spinning chenille yarn is different from spinning other yarns. Therefore, the operation requirements are also different. The requirements and precautions are as follows:

a) During the operation, the operator shall strengthen the tour, check whether the cutting edge of the lint cutting blade is blunt at any time, and replace it in time, otherwise the quality of lint cutting will be affected.

b) The use of spacer and roller has a direct impact on the spinning number. The operator should constantly improve the visual hand feeling ability to ensure that the spun lines are uniform.

c) Before a new spacer is used, its sides and edges should be polished flat and smooth, and then the smoothness above V11 level should be polished with sandpaper to ensure the winding and sliding of pile yarn.

d) The yarn defects caused by broken ends and parking shall be tied so that the winder can check and repair the defects. In case of defective yarn, such as wool yarn and exposed core, the process shall be adjusted in time, the equipment shall be overhauled, and the damaged bobbin tube shall be handed over to a special person for treatment.

e) Always keep the machine clean and tidy, keep the spinning channel unblocked, and prevent flying defects.

Specification:

| Item No: | chenille machine spare parts | Application: | chenille spinning parts |

| Name: | PU roller with yellow/red/green/transparent color | Color: |

Products Image:

|

|

|

||

|

||||

|

|

|||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

Packing and Delivery:

1.Carton package suitable for air and sea shipment.

2.Delivery normally is one week.

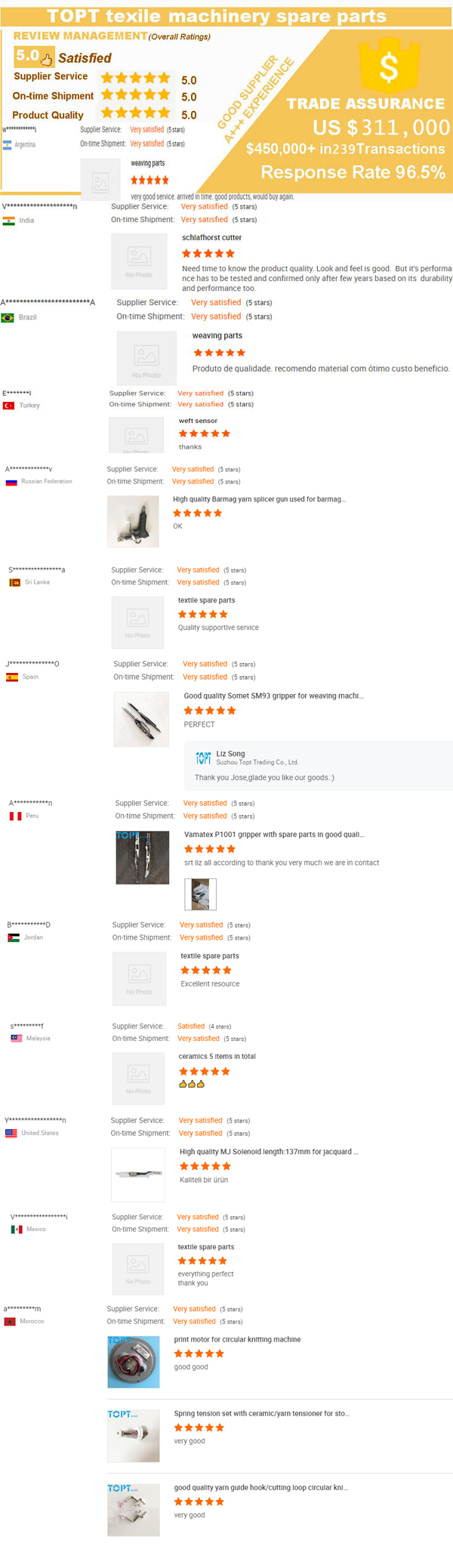

Contact us:

· Website:http://topt-textile.en.alibaba.com

· Contact:Liz Song

· Cellphone: 0086 15821395330

· Skype: +86 15821395330 whatsapp: +008615821395330

Wechat:lizisong_520

WE WILL KEEP YOU INFORMED OF OUR NEWEST PRODUCTS & WELCOME TO CONTACT US AT ANY TIME!