- Use:

-

warping machinery

- Type:

-

yarn guide teeth

- Warranty:

-

3 months

- Condition:

-

New

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, textile spare parts

- Video outgoing-inspection:

-

Not Available

- Machinery Test Report:

-

Not Available

- Marketing Type:

-

Ordinary Product

- Place of Origin:

-

Zhejiang, China

- Brand Name:

-

topt

- Quality:

-

Guaranteed

- Color:

-

pink

- Material:

-

metal

- Payment Term:

-

T/T, Paypal, Western Union

- Delivery time:

-

3-5 Working Days

- MOQ:

-

50pcs

- Application:

-

yarn separating

- Product name:

-

yarn guide teeth

- Machine Type:

-

warping machinery

- Service:

-

on line service

- After Warranty Service:

-

Online support

- Local Service Location:

-

None

- Showroom Location:

-

None

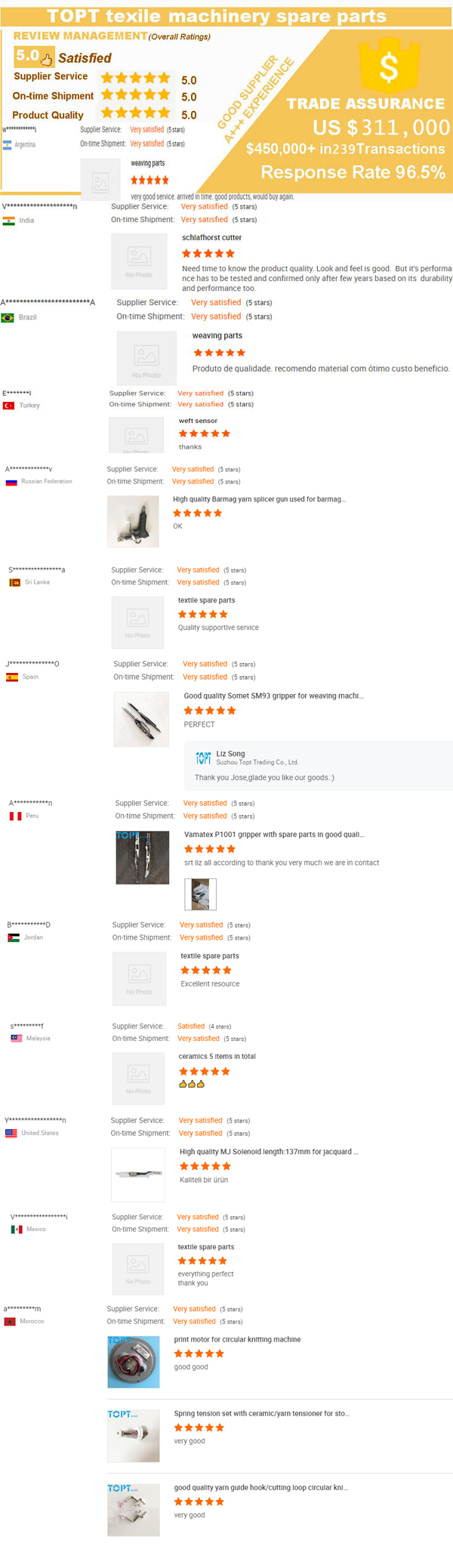

Introduce for warp machine:

It can be divided into two categories: one is the traditional drum friction drive warping machine, and the other is the new warping machine directly driven by the warping shaft.

Roller type

The pressurization method of drum friction drive warping depends on the weight of heavy hammer, warp shaft arm and warp shaft itself. After the transformation of the old machine, the horizontal pressurization method is adopted.

New high speed

The warp drawn from the bobbin on the bobbin frame first passes through the gap between the yarn gripper and the column, passes through the broken end detector, passes forward through the yarn guide porcelain plate, then passes through the yarn guide rod, passes through the telescopic reed, bypasses the length measuring roller and is wound onto the warp shaft. The warp shaft can be directly dragged to the by the variable speed motor. When the winding diameter increases, the speed measuring generator connected with the length measuring roller sends out the signal of speed change, and the speed of the motor is automatically reduced by the electrical control device to keep the winding speed of the warp shaft constant.

Slitting warping machine

After the yarn is led out from the bobbin on the bobbin frame, it is wound onto the drum one by one through the guide rod, rear reed, guide rod, photoelectric broken end self-stop film, split reed, fixed amplitude reed, length measuring roller and guide roller. During shaft reversal, all warp yarns on the drum are withdrawn from the counterclockwise direction according to the rotation of weaving shaft according to double dotted line, and then rolled onto the weaving shaft.

Specification:

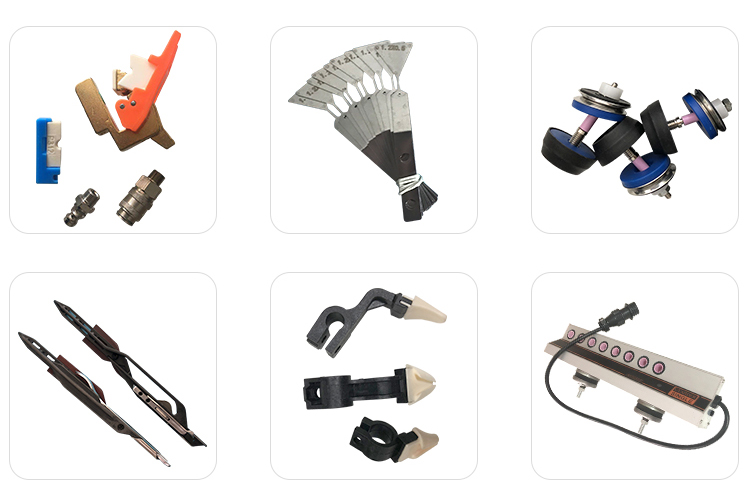

| Item No: | separate yarn | Application: | warping machinery |

| Name: | yarn guide teeth | Color: | pink |

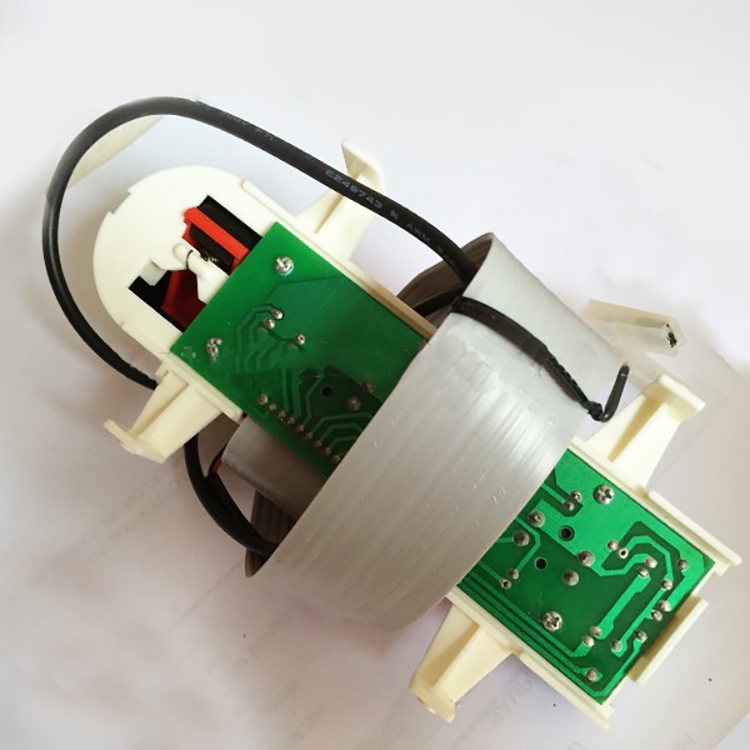

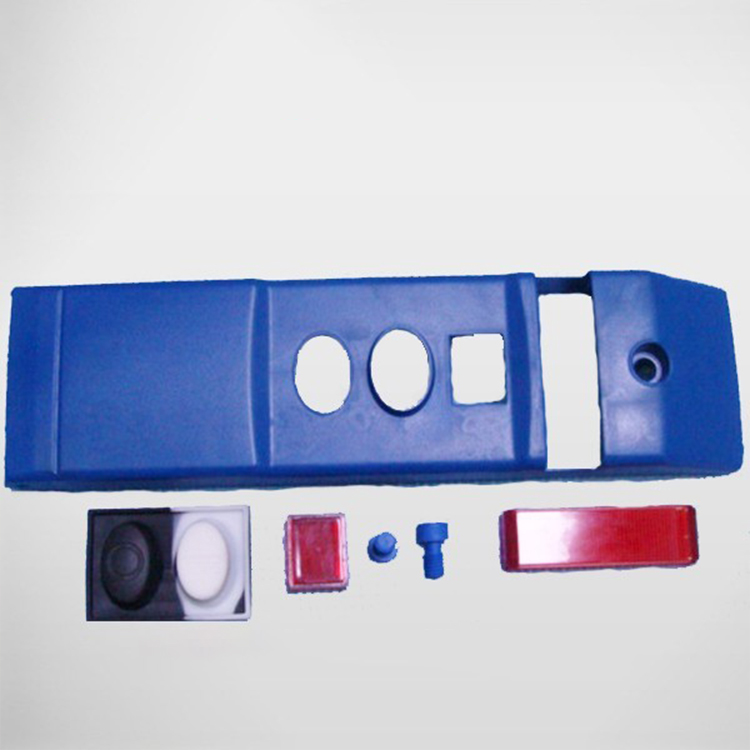

Products Image:

Packing and Delivery:

1.Carton package suitable for air and sea shipment.

2.Delivery normally is one week.

Contact us:

· Website:http://topt-textile.en.alibaba.com

· Contact: Simple Peng

· Cellphone: 0086 15901975012

- weChat: 008615901975012

·